Learning from nature:

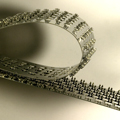

Metaklett, a steely hook and loop fastener

02.09.2009, Press releases

Hook and loop fasteners have become commonplace features of both industry and households. However, they have one snag: they are too weak for many applications. Hook and loop fasteners made of spring steel have now been developed at the Institute of Metal Forming and Casting of the Technische Universitaet Muenchen. These fasteners are resistant to chemicals and can withstand a tensile load of up to 35 tonnes per square meter at temperatures as high as 800°C.

Over 60 years ago when the Swiss engineer and inventor George de Mestral was painstakingly removing burrs from his dog’s coat after a hunting excursion, he stumbled on an ingenious idea. Based on the model he had observed in nature, he constructed a fastener from numerous small hooks and loops, which he subsequently named “velcro." “The unbeatable advantage of a hook and loop fastener is that it is easy to close and open again,” explains Josef Mair, a scientist from the Institute of Metal Forming and Casting (utg) at the TU Muenchen. Because of this, the hook and loop principle is put to a very wide range of uses, e.g. as an alternative to shoe laces, to secure medical bandages and prostheses, and for the cable boots used in automotive and aviation electronics.

Unfortunately, standard synthetic hook and loop fasteners are not very resistant to heat and aggressive chemicals. “Things can get very hot, for example, in the automotive sector. A car parked in direct sunlight can reach temperatures of 80 °C, and temperatures of several hundred degrees centigrade can arise around the exhaust manifold. Aggressive disinfectants are used for cleaning purposes in hospitals, and traditional hook, and loop fasteners are too weak for use in the construction of building façades,” explains Mair. Under the leadership of Professor Hartmut Hoffmann and as part of a joint project launched in 2005 with the Federal Ministry of Education and Research (BMBF) in close cooperation with partners from industry, the utg has developed a solution to this problem: the result is Metaklett, the hook and loop fastener made of steel.

Temperatures in excess of 800 °C and aggressive chemical solutions do not pose any problem for Metaklett, which also offers adhesive strength of up to 35 tonnes per square meter when tensile force is applied parallel to the fastener surface. When it is applied perpendicular to the fastener surface, Metaklett can still withstand a force of seven tonnes per square meter. Moreover, like a standard Velcro® fastener on a child’s shoe, it can be opened and closed again without the help of any tools.

The researchers opted to use spring steel, which unites high ductility with high strength, as the material for their fastener. They created various three-dimensional models for the optimum interlocking of the fastener elements on the computer. They then built the most promising candidates as prototypes and subjected them to comprehensive tests. Around 40 variations of the geometry referred to as “Flamingo” alone were tested on the computer. The researchers studied its adhesive strength and reaction to extreme temperatures to establish the limits of its resilience.

Two of the tested models ultimately made the grade: a spring lock, the Flamingo, and a hook and loop system known as the “Entenknopf” (“duck’s head”). Both consist of 0.2-mm-thick hook tape and loop or perforated tape of the same thickness. The “duck’s head” model is based on the traditional synthetic hook and loop system. Numerous delicate steel hooks can attach at any angle to the loops in the perforated metal loop tape.

The second variant, the Flamingo, is even more stable. It consists of wider hook elements that snap into the openings in a perforated tape. They are bent in such a way that they deform elastically under light pressure and glide into the holes like the synthetic buckles on backpack straps. Once inserted, they return immediately to their original form and, thanks to their sprung splaying arms, they resist back pull like an expanding rivet.

In order for the hooks to be able to snap into place, they must first, however, be positioned at the correct angle, that is parallel or perpendicular to the perforated tape. Depending on the direction of the applied force, this fastener can withstand a load of 7 to 35 Newtons per square meter. Following an initial loss of around 20 percent during the first ten tests, the adhesive strength remained constant in the numerous repetitions.

“The animal names arose as a way of differentiating between the multifaceted models. The hook forms of the two systems are vaguely reminiscent of a duck’s head and a flamingo standing on one leg,” explains Mr. Mair. The scientists have also come up with a third alternative, the “hybrid” model which combines a steel hook tape with a synthetic loop tape and is suitable for the secure and reversible fastening of textiles.

Metaklett is basically suitable for use in all areas that require easily opened but stable fasteners, for example air-conditioning and ventilation systems in building services engineering and automotive construction. As the Jury of the German Stahl-Innovationspreis (Steel Innovation Award) noted in its appraisal of the project: “Metaklett is suitable for a wide variety of applications, in which the combination of simple production and a high level of resilience in the fastener is crucial.” The metal hook and loop fastener succeeded in overcoming over 100 competing projects on June 30, 2009, to take third place in this award process, which only takes place every three years.

METAKLETT has been funded by the German Ministry of Education and Research (BMBF) within the framework "Research for the production of tomorrow". Industrial partners are Reinz-Dichtungs-GmbH, Hölzel Stanz- und Feinwerktechnik as well as Koenig Verbindungstechnik GmbH. During the project Dr. Christoph Hein, antecessor of Josef Mair, earned his doctor degree with his dissertation „Systematische Untersuchungen zu metallischen Klettverbindungen“ (utg-Forschungsberichte – Band 48 -Technische Universität München, Hieronymus Verlag, Garching, 2008, ISBN 978-3-89791-394-3).

Link:

High resolution picture:

http://mediatum.ub.tum.de/node?cfold=810322&dir=810322&id=810322

Contact:

Dipl.-Ing.(FH) Josef Mair

Technische Universitaet Muenchen

Institute of Metal Forming and Casting (utg)

Walther-Meißner-Str.

D 85747 Garching, Germany

Tel.: +49 89 289 14540

Fax: +49 89 289 14547

E-Mail -

Internet

Kontakt: presse@tum.de

More Information

| 090902_metaklett_pw.pdf |

Presseinformation (DE),

(Type: application/pdf,

Size: 183.6 kB)

Save attachment

|

|

| 090902_metaklett_pw_en.pdf |

Press release (EN),

(Type: application/pdf,

Size: 201.6 kB)

Save attachment

|

|

| 090902_animation_flamingo.flv |

Animation Prinzip "Flamingo" (Flash-Format, 1,5 MB),

(Type: application/octet-stream,

Size: 1.5 MB)

Save attachment

|

|

| 090902_animation_entenkopf.flv |

Animation Prinzip "Entenkopf" (Flash-Format, 0,5 MB),

(Type: application/octet-stream,

Size: 407.2 kB)

Save attachment

|